- On sale!

Investigation of energy absorption properties of metal honeycomb houses and development of analytical models to investigate the energy absorption behavior of honeycomb houses using ls dyna software is one of the important issues to be studied.

It also aims to investigate the energy absorption properties of metal honeycomb houses

Security policy (edit with Customer reassurance module)

Delivery policy (edit with Customer reassurance module)

Return policy (edit with Customer reassurance module)

Investigation of energy absorption properties of metal honeycomb houses and development of analytical models to investigate the energy absorption behavior of honeycomb houses using ls dyna software is one of the important issues to be studied.

It also aims to investigate the energy absorption properties of metal honeycomb houses

List of topics

Sandwich Panel. 4

Application of Sandwich Panel. 5

Properties of Sandwich Panel. 5

Types of sandwich panels. 6

Sandwich Panel Sandwich 6

1-3-1- Wall Panel Sandwich 6

1-3-2- Refrigerator Panel Sandwich 6

1-3-3- Thickness of sandwich panel. 7

1-3-4- Polyurethane foam sandwich panel. 7

Methods of making sandwich panels. 8

4.4.1 Container Method 8

1-4-1-1. Polyurethane Container Device. 8

1-4-1-2. Polystyrene Container Machine. 9

1-4-2- Discontinuing Method 9

1-4-2-1. Polyurethane Discontinuous Production Line. 9

1-4-2-2. Polystyrene Discontinuous Production Line. 10

1-5- Types of ingredients in the sandwich panel core. 10

1-5-1- Types of sandwich panel coatings or outer layers 10

1-6- Types of sandwich panels. 11

2. Literature Review

2-1- Honeycomb .. 15

Reversing Cylindrical Shells: Alexander's Method 20

Buckling of hexagonal structures. 22

2-4- Analytical Model of Honeycomb without Rolling Deformation

2-5- Honeycomb Analytical Model Considering Rowling Deformation 28

2-6- Experimental Testing 30

3. Finite element analysis. 33

3.1 Sandwich Panel Structure 34

Core Analysis. 37

Characteristics of Honeycomb Sandwich Panels 38

3-4- Strength tests for honeycomb sandwich panels 39

3-5. Three point bending tests. 40

3-6- Analysis of three-point bending tests 41

3.7 Real distribution of shear stress 45

3.8 Buckling Test Analysis of Pressure Loading 49

3.9 Compression Test Due to Transverse Loading 49

3-10- Analysis of Compression Test Due to Transverse Loading 51

3-11- Increased strength. 52

4- Examination of fatigue modes in sandwich panels. 54

Work History 55

Review the sandwich panel and its applications

Sandwich Panel

Sandwich Panel [1] or Aluminum Composite Panel (ACP) as well as Aluminum Composite Materials (ACM) are composed of lightweight composites comprised of two layers bounded at one end and a layer between them. Insulated (like a hamburger sandwich on which the hamburger bread is coated on both sides) This insulation is soft and flexible. Sandwich panels are made from materials such as polyurethane, polystyrene, stone wool and glass wool.

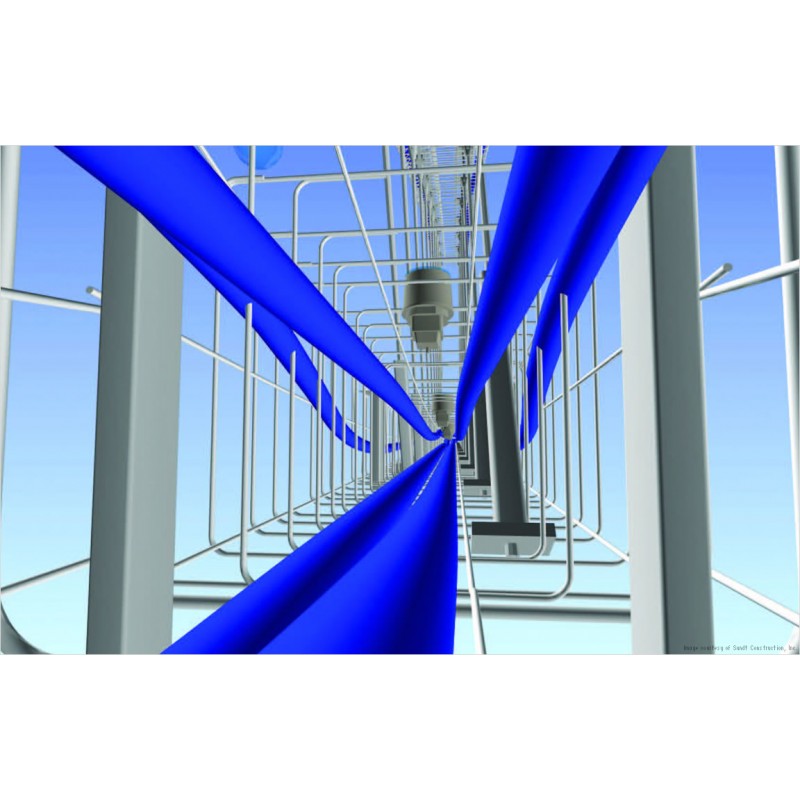

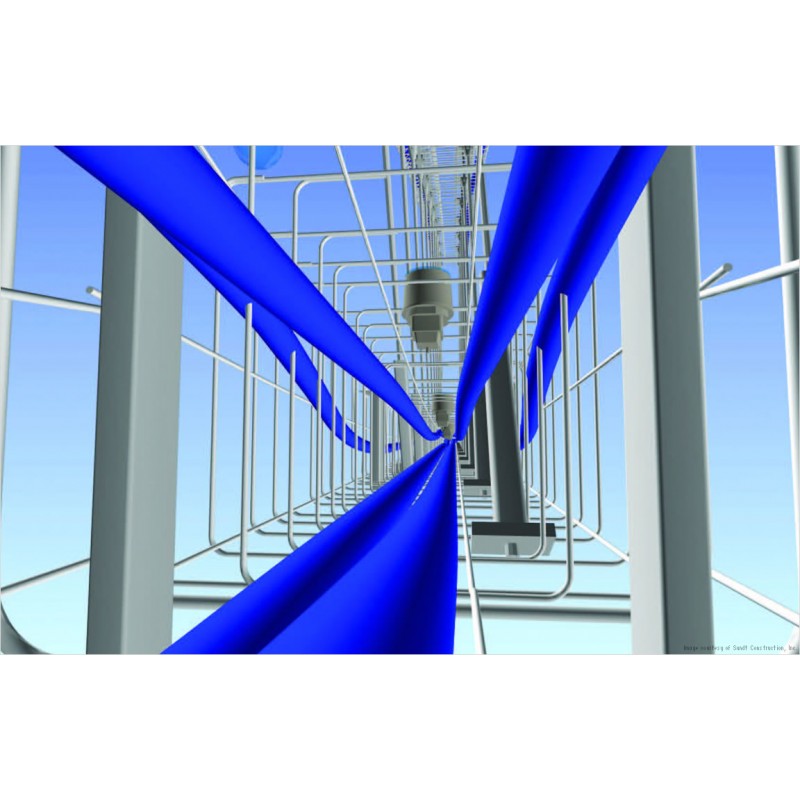

Figure 1-1 is an example of a sandwich panel

Application of Sandwich Panel

Use of sandwich panels in a variety of cold houses and refrigeration industries. Workshop offices, sanatorium, sanatorium, clinic, field office, mobile repair shop, security post, one- and two-story villas - relief units in critical times such as earthquakes, niches, walls and ceilings in production halls. , Office Buildings & Hotels, Dormitories, Containers Sandwich Panel Application in Multi-Wall Tanks, Nursery Coverage, Homes & Villas, Industrial Sandwich Panel, Nursery Coverage, Club & Cold House, Critical Assistance Units such as Earthquake, Residential Buildings , Grain warehouses, schools and clinics Mobile, cold meat and dairy, mobile homes and caravans, indoor swimming pools, sports halls, walls and roofs of industrial buildings, walls and ceilings and walls of internal divisions in the factory and office rooms. Sandwich panels also have a variety of uses in a variety of industries, including construction of containers, containers, fixed and removable refrigerated receptacles, prefabricated structures and houses, temporary accommodation camps, niches, steel structures, space structures, warehouses and docks, sports complexes, Industrial and manufacturing plants, industrial and semi-industrial cold stores.

Properties of Sandwich Panel

Among its properties are the following:

1: High energy insulation 2: Lightweight compared to other materials 3: Very low cost compared to traditional materials 4: Washable 5: Easy to install and run 6: Various colors 7: Proper sound insulation 8: High resistance to earthquake shear forces 9: Extended shelf life

Data sheet