- On sale!

The advancement of various industries and the ever-increasing needs of mankind have led researchers and craftsmen to use new production methods to achieve the required products as quickly as possible. The use of turbulent friction welding to bond aluminum and steel sheets used in the automotive industry has received much attention among these new methods. This is due to the FSW's ability to produce high quality welds and

Security policy (edit with Customer reassurance module)

Delivery policy (edit with Customer reassurance module)

Return policy (edit with Customer reassurance module)

5- Summary of the Thesis: (Problem, Hypotheses, Purpose of Implementation, Justification of Project Necessity)

The advancement of various industries and the ever-increasing needs of mankind have led researchers and craftsmen to use new production methods to achieve the required products as quickly as possible. The use of turbulent friction welding to bond aluminum and steel sheets used in the automotive industry has received much attention among these new methods. This is due to the FSW's ability to produce high quality welds and unique advantages. This new welding process is a solid-state welding method. In friction-perturbation (FSW) welding, a cylindrical tool with a pin embedded in the forehead is welded at the beginning of the two-sheet connection line. This cylindrical tool moves at a two-piece edge with high rotational speed and proportional force downward. The edges of the dough are shattered by the heat generated by the dough friction and the rotating tool shakes the dough material forward. This way the welding is done between two pieces. Today, friction stir welding is considered as a superior method for bonding curved surfaces, sections of different thicknesses and objects made of different metal materials. This method of welding has already taken its place in the aerospace and rail industries and is rapidly expanding in the auto industry.

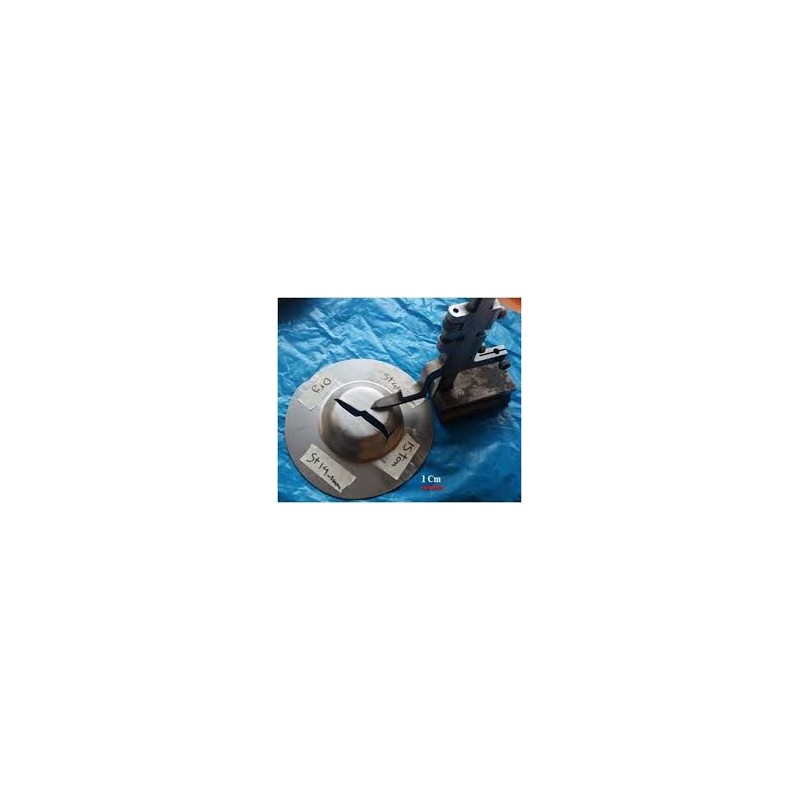

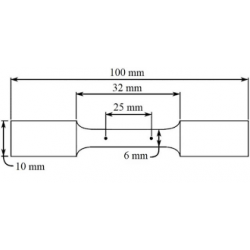

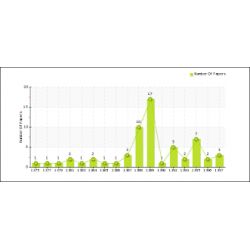

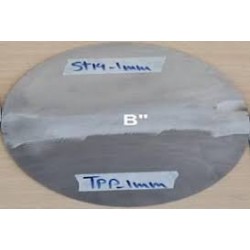

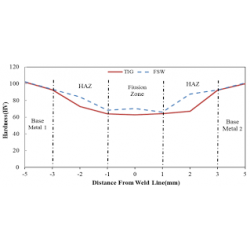

In this project, we first try to experimentally test the welding ability of st14 steel sheets from 1 to 2 mm thick, which are widely used in the manufacture of corrugated bodies. Then study the parameters of this new welding process. Next, to investigate the most important parameters of this process, such as rotational speed, linear welding speed and geometry of the test instruments, be designed by the Design of Experiments (DOE) method and determine the appropriate parameters for frictional st14 anchors. Finally, by conducting a stress test with a hemispherical bent, the shear stress is investigated and the corresponding FLD diagram is drawn and mechanical tests such as, tensile testing, and metallurgical tests such as, microhardness and metallography are performed to evaluate the health of the welds. And the mechanical properties of the sheets produced.

Keywords: Friction-Turbulence Welding, Test Design Method (DOE), st14 steel

Keywords: st14, Optimization, Design of experiment, FSW Welding